A set like the explosion-proof socket set is designed to minimize ignition risks when technicians perform routine fastening tasks. In these industries, non sparking sockets are often selected to avoid friction-based ignition and maintain safe working conditions, especially during maintenance operations where continuous tool contact and unpredictable environmental factors can increase overall hazards.

Materials, Structure, and Safety Principles

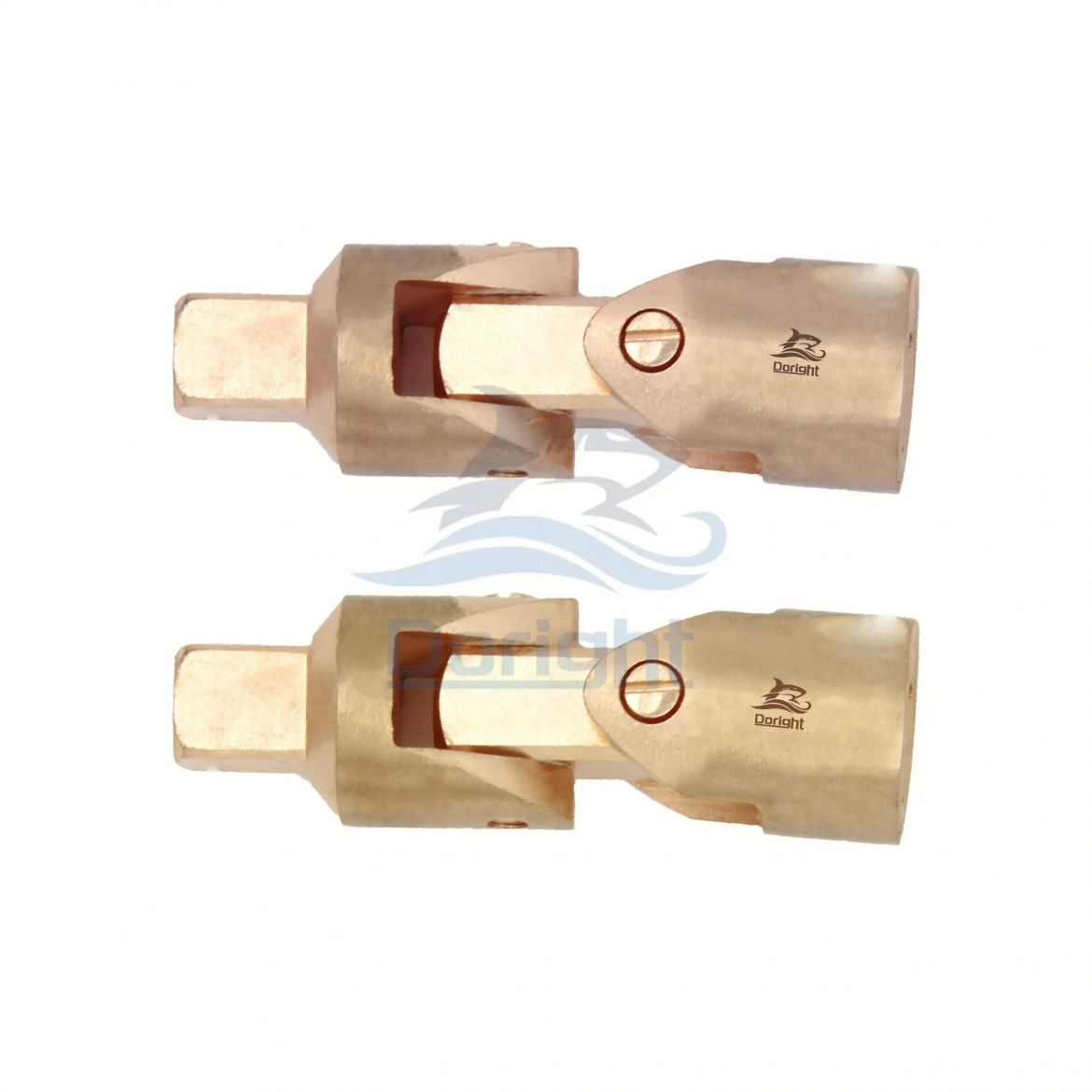

Manufacturers that serve demanding sectors, such as oilfield equipment suppliers and hardware tool distributors, provide tools built around specific alloys and mechanical principles. A typical explosion-proof socket set often incorporates aluminum bronze or beryllium copper, both known for reducing the chance of spark formation under impact or abrasion. They also design components to meet recognized standards so that users receive long-term reliability. For example, Doright integrates the D.112 Universal Joint into certain tool configurations. This joint—made from Aluminium Bronze Alloy and Beryllium Copper Alloy and aligned with DIN3123—supports shafts that transmit rotary motion, allowing technicians to reach confined angles while maintaining controlled torque. Tools like these complement non sparking sockets used in daily maintenance routines where safety margins are critical.

Application Scenarios in Industrial Fields

In sectors such as petroleum refining, pipeline maintenance, heavy machinery service, and offshore operations, teams rely on an explosion-proof socket set to perform tasks without interrupting equipment flow. They avoid unnecessary risks by selecting tools that remain stable even under frequent rotational loads. This is where components such as the D.112 Universal Joint add operational convenience. Its flexibility helps users access bolts positioned in restricted areas, supporting safer and smoother workflows. Industrial distributors often highlight these advantages when presenting product options to engineering teams and technicians.

Conclusion

Choosing appropriate tools for hazardous locations requires understanding how safety features combine with mechanical performance. Explosion-proof tools, including non sparking sockets and comprehensive kits like an explosion-proof socket set, help reduce ignition risks while supporting precise mechanical work. By aligning alloy selection, structural design, and industry standards, Doright delivers products—such as the D.112 Universal Joint—that match the needs of demanding industrial sectors. This approach ensures that hardware distributors and oil and gas suppliers can offer reliable solutions to teams working in environments where safety cannot be compromised.