In the high-stakes world of automotive injection molding, the gap between a theoretical design and a road-ready component is bridged by rigorous validation. Mold testing serves as the definitive phase where engineering concepts meet physical reality, answering the critical question of whether a tool can consistently produce zero-defect parts under mass production conditions. For OEMs and Tier 1 suppliers, robust T0-Tn trials are essential to identify thermal imbalances, venting issues, and dimensional deviations before they disrupt the assembly line. By systematically analyzing equipment parameters and verifying mold functionality, manufacturers ensure that safety-critical components and Class A surfaces meet stringent tolerances, thereby minimizing risk and optimizing the total cost of ownership.

Implementing Scientific Standards in Process Control

Transitioning from “art to part” requires a data-driven approach. By adopting scientific molding principles, manufacturers can decouple the complex variables of injection, packing, and cooling to establish a stable universal process window that guarantees repeatability across millions of cycles.

Decoupled Molding Strategy Implementation

Traditional molding often relies on operator intuition, leading to inconsistencies. In contrast, the decoupled molding strategy separates the fill, pack, and hold phases to isolate variables. The primary goal is to fill the automotive injection mold cavity 95–98% by volume using velocity control, then switch to pressure control for the final packing. This method minimizes internal stress and flash while ensuring dimensional stability. For instance, establishing a viscosity curve allows engineers to determine the optimal injection speed where material viscosity is most stable. Historical data indicates that implementing decoupled molding protocols can reduce scrap rates by over 90%, transforming a process with 6.5% waste into one with less than 1% rejection, significantly lowering costs for plastic injection molding automotive industry projects.

Real-Time Cavity Pressure Monitoring

To maintain automotive injection molding solutions at OEM standards, real-time process control is non-negotiable. Installing cavity pressure sensors provides a direct view of what is happening inside the tool. These sensors trigger the V/P (Velocity to Pressure) switchover based on actual cavity pressure rather than machine screw position, which can fluctuate due to material viscosity changes or check ring wear. This technology is particularly vital for automotive rubber injection molding and complex thermoplastics, as it detects short shots or flash instantly. Automated monitoring systems can reject non-conforming parts immediately, ensuring that 100% of the shipped components meet the rigorous specifications required by the injection molding automotive industry.

Validation Protocols and Structural Optimization

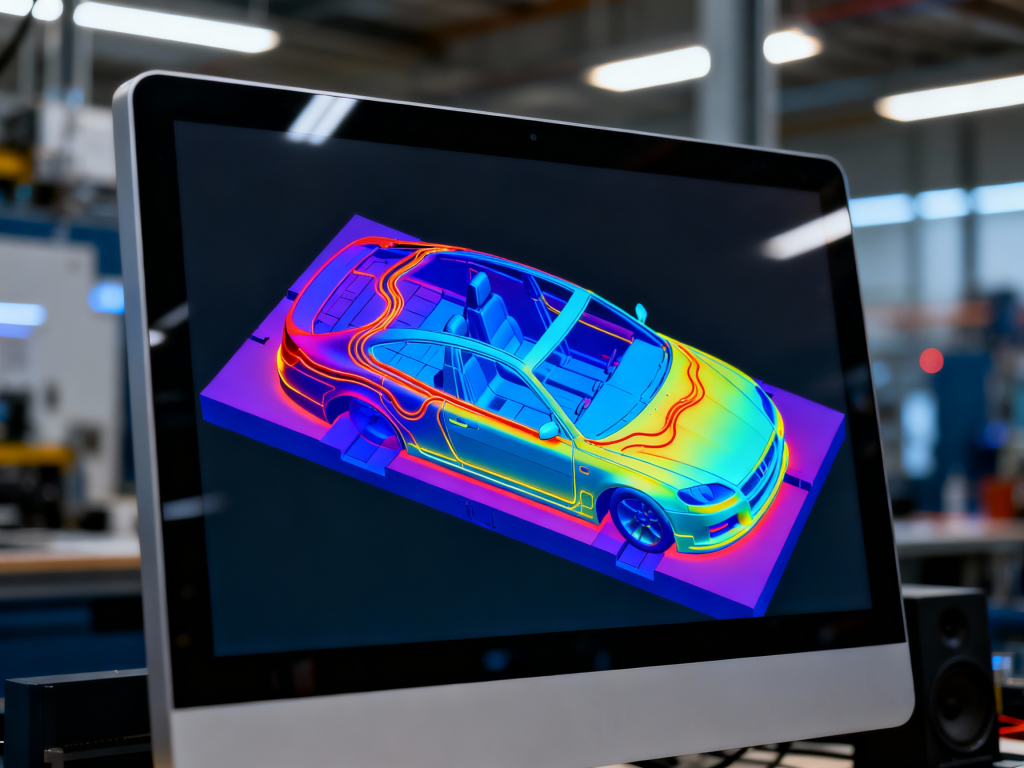

Before steel is cut, virtual validation minimizes the risk of costly rework. By integrating simulation with advanced thermal management strategies, manufacturers can compress development timelines and enhance the structural integrity of complex automotive components.

Virtual Validation and Simulation Protocols

The digital twin concept has revolutionized the automotive injection molding suppliers landscape. Advanced Moldflow analysis predicts potential defects such as air traps, weld lines, and warpage in fiber-reinforced composites before the first physical trial. This virtual tryout (VTO) significantly compresses the T0 (first trial) to T1 (first functional sample) timeline. By accurately calculating clamping forces and flow fronts in software, engineers can prevent flash and optimize gate locations. Studies show that comprehensive virtual validation can reduce physical mold trial iterations by up to 50%, accelerating time-to-market for critical vehicle programs.

Structural Thermal Management Optimization

Thermal management is the single largest factor in cycle time and part quality. Implementing conformal cooling channels—often manufactured via 3D metal printing—allows coolant to follow the complex contours of the part, which traditional drilled channels cannot reach. This is crucial for maintaining the aesthetic quality of interior lenses or the dimensional accuracy of structural brackets. Data confirms that replacing conventional cooling with conformal systems can reduce cycle times by 10% to 40% while eliminating hot spots that cause differential shrinkage. Effective thermal balance also improves gas evacuation efficiency, preventing diesel effects and burn marks on high-gloss finishes.

Livepoint Tooling: Precision Automotive Manufacturing Solutions

With over 23 years of expertise, Livepoint Tooling stands as a premier partner for global automotive OEMs, delivering IATF 16949-certified precision molds and injection molding services.

OEM-Grade Manufacturing Capabilities

Livepoint specializes in high-complexity tooling, supporting renowned brands like Tesla, Ferrari, and Volkswagen. Their capabilities span from rapid prototyping to mass production of critical components, including dashboards, lighting systems, and fluid reservoirs. The company utilizes advanced 5-axis CNC machining to achieve mold tolerances as tight as ±0.01mm, ensuring flawless part fit. By offering a true one-stop solution—from tool design and fabrication to surface finishing and assembly—Livepoint reduces supply chain complexity. Contact our engineering specialists today to implement rigorous mold testing protocols that guarantee the precision and durability required for your next automotive manufacturing project.