The CNC drilling machine is more than a hole-maker, and HUAHUA CNC’s SKH-612NS model, built in their Foshan factory, proves this with its multi-functional capabilities. As part of a line producing 8,500 machines annually, this CNC drilling machine handles tasks beyond drilling, adapting to diverse production needs with remarkable flexibility.

Six-Sided Processing for Comprehensive Work

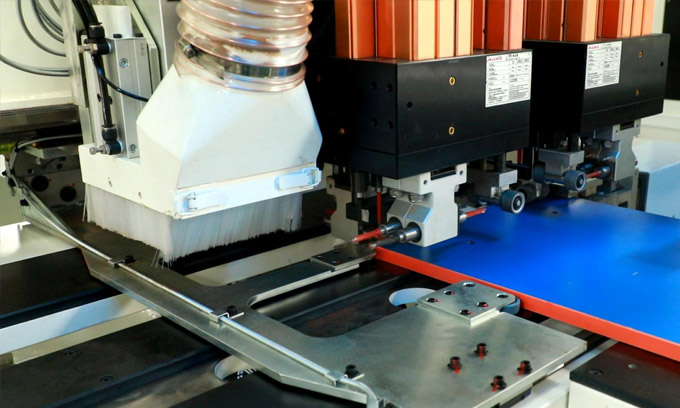

This CNC drilling machine excels at six-sided machining, tackling drilling, grooving, and milling with ease. Equipped with 3.5kw milling spindles (one top, one bottom) and a range of drilling bits (12 vertical + 8 horizontal per top group, 9 vertical bottom bits), it handles everything from hinge holes to decorative grooves in a single pass. This eliminates the need for multiple machines, saving workshop space and streamlining workflow transitions between tasks.

Flexible Sizing for Varied Projects

It accommodates workpieces from 10mm to 48mm thick, 50mm to 1200mm wide, and 250mm to 4200mm long. This broad range makes the CNC drilling machine suitable for small parts like drawer handles, medium-sized cabinet doors, and large panels for wardrobes or office furniture, ensuring it remains useful as production demands shift over time.

Customizable with Optional Add-Ons

To meet specific needs, the CNC drilling machine offers optional features: side slotting, surface slotting, an ATC tool changer, and a side discharge lifting table. These add-ons let manufacturers tailor the machine for niche tasks, from intricate cabinet details requiring precise grooves to large-scale furniture production needing efficient material handling.

Conclusion

HUAHUA CNC’s CNC drilling machine shines for its versatility, handling six-sided processing and adapting to custom needs. It’s a one-stop solution for streamlining workflows by combining multiple tasks into a single, efficient tool, making it ideal for workshops aiming to expand their production capabilities.